Maschinery of the Graute GmbH

Opening Blending

Opening Blending

-

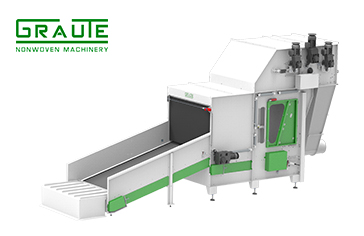

Bale Opener (BO / WBO)

The Bale Opener ensures a gentle opening of strongly pressed fiber bales as well as a thorough mixing and equalization of the starting fibers. If required, the Bale Opener can be equipped with a weighing unit, mixing belt and Continuous Mixing Opener (CMO) for metering and mixing several fiber types.

-

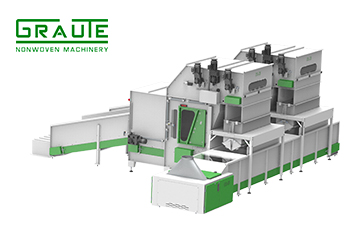

Continuous Mixing Opener (CMO-W2)

The Continuous Mixing Opener guarantees already at the first opening point a very good mix of the different fiber types as well as a gentle dissolution of the fiber flakes by continuously feeding of two fiber types. Through this newly developed mixing machine, the production capacity of the opening can be significantly increased and the mixture can be significantly improved. The use of large, space-consuming mixing boxes is no longer necessary.

-

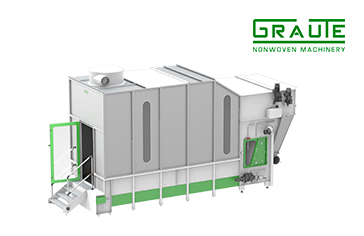

Large Volume Blender (LVB)

The Large Volume Blender is used to buffer already opened fibers to compensate for fluctuations in the production process. During buffering, the fibers are also mixed and homogenized again.

-

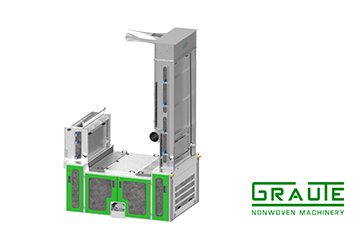

Micro Tuft Opener (MTO / MTO-M)

The Micro Tuft Opener ensures optimal quality of the end product through a gentle dissolution of the fiber flake down to the individual fiber and a thorough mixing of the fiber. For large working widths (≥ 2 m), a retractable version (MTO-M) was developed to considerably simplify maintenance, cleaning and minimize downtimes.

-

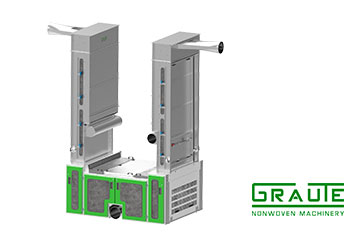

Pre Opener (PO)

The Pre Opener ensures a continuous feed of the following machines with fiber material and compensates for fluctuations in delivery of the opening line. Two feed rollers and one opener roller also pre-open the fiber.

Carding

Carding

-

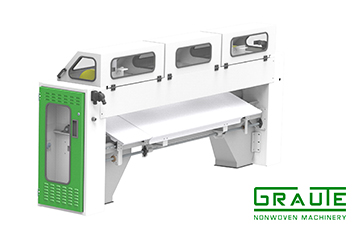

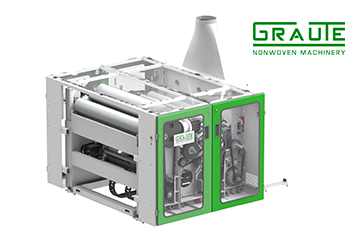

Card Feeding Unit (CFA)

The Card Feeding Unit forms a uniform fiber mat from the injected fiber flakes and for the following carding machine. The adjustable profile forming device of the CFA ensures that each point of the working width of the following machine is covered with the right amount of fibers.

-

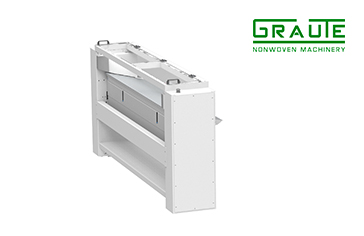

Cutting Device (CD)

The Cutting Device limits the fiber mat before the web formation by a double-sided, adjustable edge cut. The web width can be adjusted individually and the edge trimming is fed back to the process without fiber damage.

-

Weighing Plate System (WPS)

The Weighing Plate System monitors the throughput and ensures automatic weight stabilisation in the production direction.

-

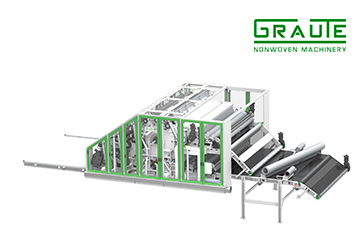

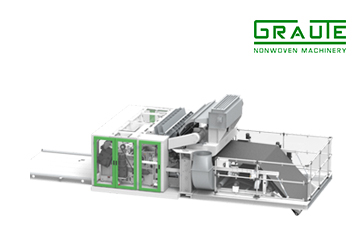

High Performance Card (HPC)

The High Performance Card can be configured individually according to your needs. The modular construction and the different delivery technologies (parallel web, randomized web, condensed fleece, randomized condensed web) guarantee the optimal solution for your product. Folding trays and the ability to retract the individual sections simplify maintenance, cleaning and minimize downtime. The use of a high-speed output also enables production speeds of up to 250 m/min.

-

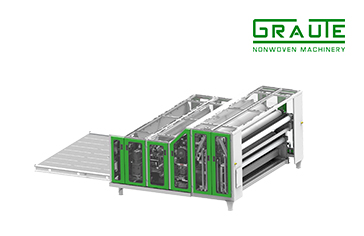

Air Lay Card (ALC)

The Air Lay Card creates a very good MD - CD ratio due to the aerodynamic fleece formation. Almost all types of natural and chemical fibers can be processed into non-woven fabrics with a weight up to 300 g / m². Folding trays and the ability to retract the individual sections simplify maintenance, cleaning and minimize downtime.

-

Random Card (RC)

The Random Card combines the advantages of aerodynamic web formation with mechanical web removal by rollers. In addition to chemical fibers it can also process 100% natural fibers such as cotton. The isotropic arrangement of the fibers allows for improved strength in the final product. Folding trays and the ability to retract the individual sections simplify maintenance, cleaning and minimize downtime.

-

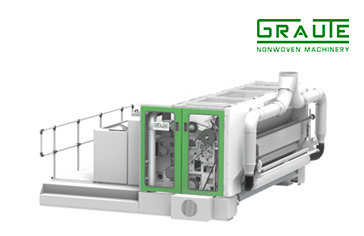

Air Web Former (AWF)

The Air Web Former is a machine for the production of voluminous thick nonwovens weighing up to 5,000 g / m². Almost all types of natural and chemical fibers can process. The maintenance-friendly design and the ability to retract the individual sections simplify maintenance, cleaning and minimize downtime.

Webforming

Webforming

-

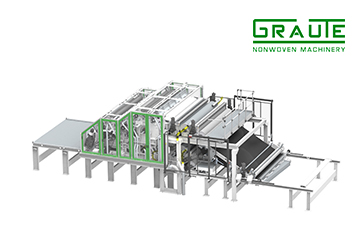

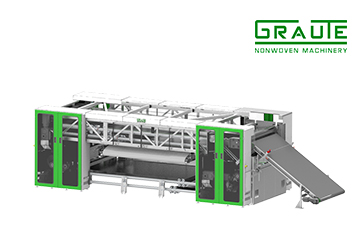

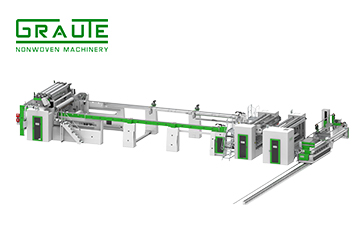

Cross Lapper (CLB)

The Cross Lapper impresses with its high smoothness due to the particularly highly stiff construction. A very low mass of moving parts, for example, by using rollers made of glass fiber reinforced plastics allows very short increasing and braking times. The profile forming system ensures precise control of the web weight over the entire laying width.

-

Web Drafter (WD)

The Web Drafter has the task to reorient the fibers and to stretch the entire web. Multiple stretching points allow to pull the material apart very gently so that the line speed and the throughput can significantly be increased.

-

Condensing Roll System (CRS)

The Condensing Roll System was specifially designed for an extension to a Rieter C60 / C70 card. It increases the grammage and improves the MD - CD ratio by reorienting the fibers. The Condensing Roll System with a Rieter Card is often used in conjunction with an Air Lay Card, in order to be able to produce cost-effective multilayer webs. A particular advantage of this is that with a 3-layer fleece, such as in the production of cotton pads, the middle layer can be equipped with up to 70% recycled fiber with the help of the Air Lay Card.

Winding / Slitting

Winding / Slitting

-

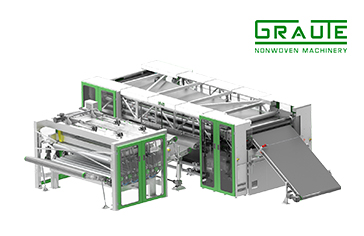

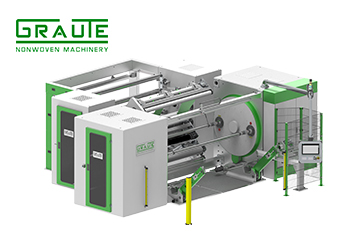

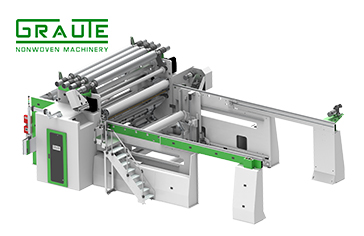

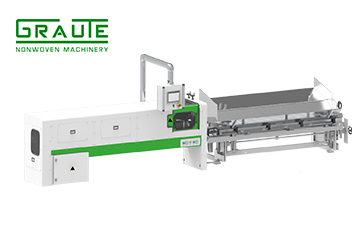

Automatic Turret Winder (ATW)

The Automatic or Fully Automatic Turret Winder (ATW) is suitable for continuous material winding behind a production line. Thanks to its special design and the right-angled cut, the fully automatic cross-cutting and engaging system guaranteed that the new web is fed and laid onto the unprepared winding core safely. In addition, the automatic turret winders are also used for the production of ready to sell rolls during inline operation.

The semi-automatic or fully automatic slitting systems required for this are optionally available.

-

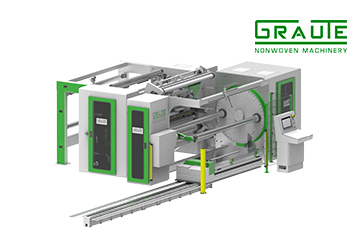

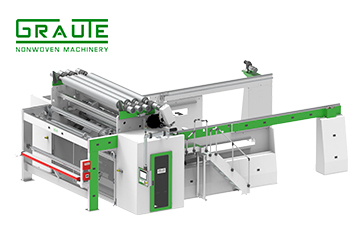

Automatic Turret Arm Winder (TAW)

The Automatic Turret Arm Winder (TAW), as the little brother of the Automatic Turret Winder (ATW), has similar prerequisites (Teilsatz entfernen). Thanks to its special design and the right-angled cut, the fully automatic cross-cutting and engaging system guaranteed that the new web is fed and laid onto the unprepared winding core safely. In addition, the Automatic Turret Winders are also used for the production of ready to sell rolls during inline operation.

The semi-automatic or fully automatic slitting systems required for this are optionally available

-

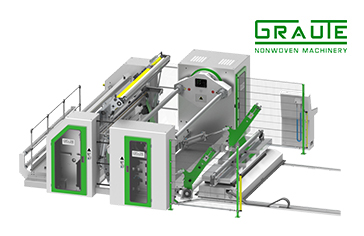

Automatic Turning Plate Winder (TPW)

The Automatic Turning Plate Winder (TPW) is a cost-effective alternative to the standard Turret Winder and is suitable for winding speeds of up to 300 m/min. Thanks to its special design and the right-angled cut, the fully automatic cross-cutting and engaging system guaranteed that the new web is fed and laid onto the unprepared winding core safely. In addition, the Automatic Turret Winders are also used for the production of ready to sell rolls during inline operation.

The semi-automatic or fully automatic slitting systems required for this are optionally available.

-

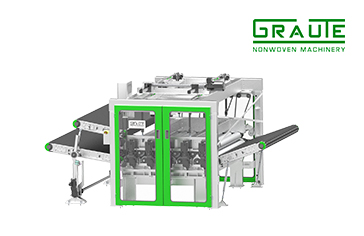

Short Roll Winder (SRW)

The Short Roll Winder (SRW) is suitable for continuous winding of short rolls behind a production line or as a stand-alone machine. The SRW guarantees an optimal cutting result at short cycle times at regular intervals, optionally with automatic or manual knife adjustment. Rewinding onto cores, which can be automatically fed and positioned from a core magazine, as well as coreless winding are possible. Automatic gluing up and transfer of the finished roll complete the fully automated winding process.

-

Automatic Turrent Unwinder (ATU)

The automatic Turret Unwinder (ATU) is particularly suitable for continuous material unwinding in front of a production or confection line and does not need any hydraulics at all.

-

Master Roll Winder (MRW)

The automatic Master Roll Winder (MRW) is characterized by high reliability and simple operation. In addition to the automatic roll change at production speed on the unprepared core, the circumferential and axial drive ensures optimal winding conditions from the winding shaft to the last layer.

A core magazine and automatic core feeding are available as an option.

-

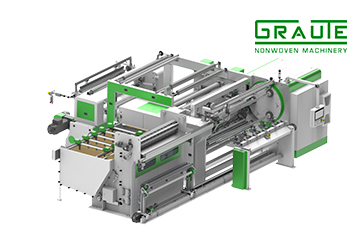

Slide Drum Winder (SDW)

Our newly developed Slide Drum Winder (SDW) combines the advantages of two different worlds by linking the sliding and carry drum principle. Thanks to its special carrier roller arrangement, the SDW guarantees optimum winding quality and produces scrap-free, ready-to-sell rolls in inline operation, even with large working widths and high winding speeds.

-

Slitter / Rewinder (RCS)

Thanks to its automation, the Slitter / Rewinder (RCS) ensures a high speed in your process. Starting with the belt unwinding, via the high-speed slitting system with automatic knife adjustment, to the finished roll winder with cross cutting unit, integrated winding shaft handling with automatic core loading and automatic roll change with finished roll transfer, all units are precisely coordinated and ensure optimum winding quality at high speeds.

-

Carry Drum Winder (CDW)

The Graute Carry Drum Winder (CDW) is particularly suitable for winding material behind a production line with large working widths and high roll weights.

-

Material Accumulator (MA)

The Graute Material Accumulator (MA) is used to store material, for example when changing reels, thus guaranteeing a continuous production process.

-

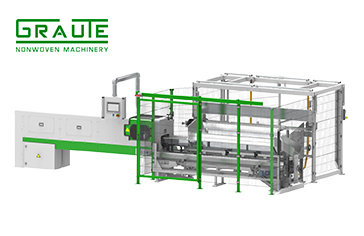

Automatic Offline System (AOS)

The Automatic Offline System (AOS) is used for the production of large rolls up to ready-made and ready to sell rolls. The AOS is equipped with automatic roll change on the Master Roll Winder and subsequent buffer for dwelling and transport of the produced large rolls. The large roll Unwinder with safe material feed to the subsequent longitudinal slitting unit, designed for high speeds, includes an automatic knife adjustment.

The finished roll winder is equipped with automatic roll change, cross-cutting/engaging system and integrated winding shaft handling as well as roller disposal. A winding core magazine and automatic core feeding for the MRW are available as an option.

-

Core Cutter (CC)

The Core Cutter (CC) is ideally suited for the clean and dust-free cutting of cardboard/plastic cores and is particularly characterized by a mature and robust construction, which guarantees a long service life and user-friendly operation. Tailored to individual requirements, different core cutters are available. Our range includes manually operated core cutters up to fully automatic ones with magazine.

Recycling

Recycling

-

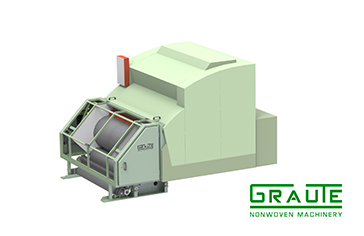

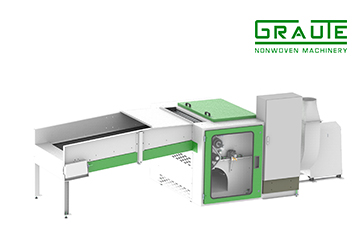

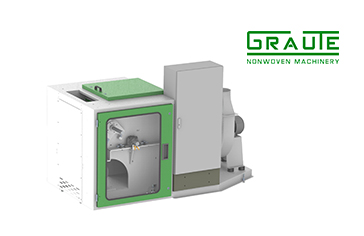

Multi Purpose Opener (MPO)

The Multi Purpose Opener has the task to open already solidified nonwoven residues and edge stripes and to feed them back into the process.

-

Edge Stripe Opener (ESO)

The Edge Stripe Opener has the task to open already solidified nonwoven residues and edge stripes and to feed them back into the process.

-

Carding Opener (CO)

The Carding Opener can be used to re-open very strong solidified materials (edge stipe, deposit rolls, etc.) which previously had to be disposed of at a cost. These materials can then be feed back into the process. This results in a considerable savings potential since no disposal costs are incurred and fewer new fibers have to be used to produce the product. As a result, the payback period of the carding opener is usually well below one year. Folding trays and the ability to retract the individual sections simplify maintenance, cleaning and minimize downtime.

MASCHINERY of the Graute DOA GmbH

Opening Blending

Opening Blending

-

Bale Opener

-

Fine Opener

Carding

Carding

-

Hopper Feeder

-

Air Lay Card

-

Scattering Devices

Oven

Oven

-

Thermobonding Oven

Recycling

Recycling

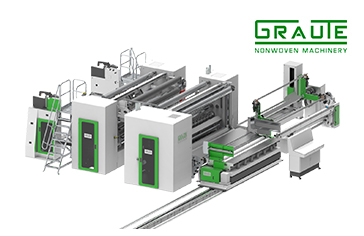

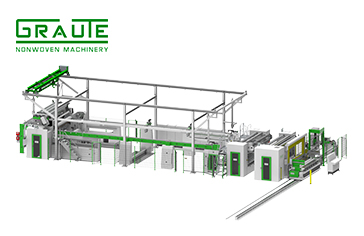

Complete Nonwoven Lines

Complete Nonwoven Lines

Further information will be added shortly. Until then, please visit Mr Angleitner's website for further details:

further details